MEP CONSULTING SERVICES

(Planning & approval Assistance)

MOEF

Builders and developers use to submit the proposed design detail with MOEF team to get the approval from MOEF authority.

Our MEP design team will assist for the basic design and drawing for submission document for details for utilities like drainage water , fire and waste management.

High Rise

Once we engaged in the project with basic planning phase with builders or investor, we assist for the approval process for the building construction.

In the process of approval ,utilities clearance is required and our MEP design team is capable to produce the documentation like design and drawing which is required for further approval process.

CONCEPT DESIGN

DBR & Schematic

At this stage , we start with basic design consideration and calculations to prepare a proposed systems which will be best fit for each project. Based on the proposed systems , we prepare the systems operational diagram or schematic for each proposed systems.

The Design Basis Report (DBR) provides essential details about the proposed system for a project. It includes basic calculations and information about major equipment like water tanks, pumps, chillers, transformers, and diesel generators (DG). It serves as a simple guide to ensure the system meets project needs.

Once the document and schematic are prepared, we share them with the client for approval.

DETAIL DESIGN

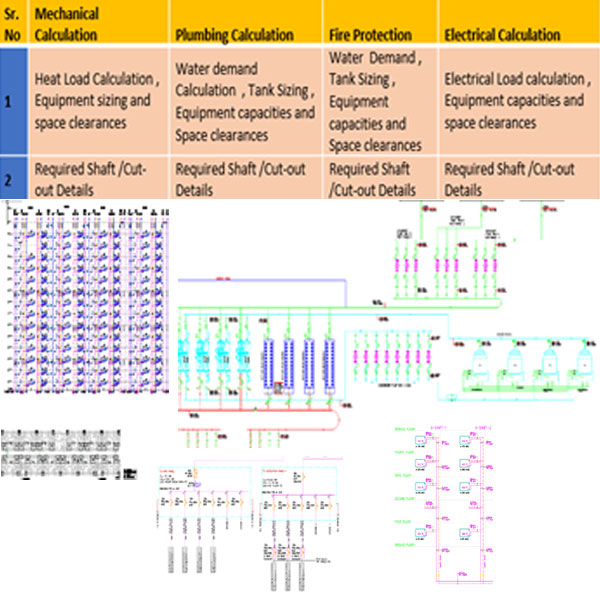

Detail Design calculation

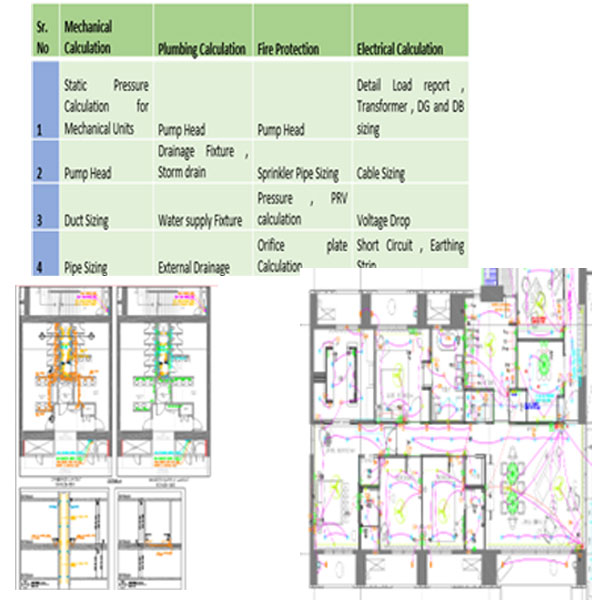

DD (Detail Design) stage is to describe the schematic with all the information line sizes and capacity of each elements of MEP systems. Design Engineering team use to produce the detail calculation for sizing with all unit capacity for drafting the detail drawings. Following calculations to be submitted in the process of detail engineering.

Detail Drawing (50 % & 100 % Detail Drawing)

DD (Detail Design) stage is to describe the schematic with all the information line sizes and capacity of each elements of MEP systems. Also to prepare the plans with all information like the size and routine with detail sections, required cutouts and capacities. MEP systems detail drawing always a package of plan, schematic drawings with detail calculation like pipe, duct size, pressure calculation and cable sizes etc. Basically the MEP elements are detailed in the plans and schematics to ensure proper design and setup.

TENDER PACKAGE

Tender Drawing

Once we receive the go-ahead from the client on the detail drawing from architect and structure, we do the internal co-ordination of all services and start to production of tender drawing. The tender drawing will have proper annotations, schedules, detailed drawing with the complete package or set for tender drawing.

Tender drawing covers the following drawings in set.

- Cover Page & Drawing List

- Detailed Schematic

- Floor plans and sections

- Detail Sheet & Schedules

BOQ with Specification (Tender Document)

Approved DD drawings can be proceeded for quantification and tendering stages. Based on the approved Detail drawing, quantity of all elements of MEP systems generated which called BOQ (Bill of Quantity). And specify all equipment’s, elements and accessories is called the specification. Tender package is always release with approved detail drawing & BOQ with specification.

CONSTRUCTION DRAWING

Construction Drawing/GFC

We generate accurate construction drawing after for the site team for execution. Construction drawing will have all the information of required executions like equipment Tag, annotation, dimensions with sectional elevations of all MEPF systems and networks.